How does the 'No-Sway, No-Bounce' Weight Distribution Hitch work?

Sway Control

Our weight-distribution hitch eliminates swaying. How? The friction cone (brake material) in the anti-sway ball housing is what eliminates sway. The material we use is similar to the material used in auto brake pads, but in its lifetime will only be subjected to a tiny fraction of what a car's brake pads would be subject to. The anti-sway housing features a tapered ball (and tapered housing), which is what makes it 'self adjusting', in other words – the heavier the load, the more downward force is placed on the tapered ball which results in more weight on the brake material causing more 'friction' to be applied. You get the exact amount of anti-sway needed whatever the weight of your load.

We recommend at least 300lbs on the tongue to allow the mechanism to be able to provide anti-sway using the friction material in the housing.

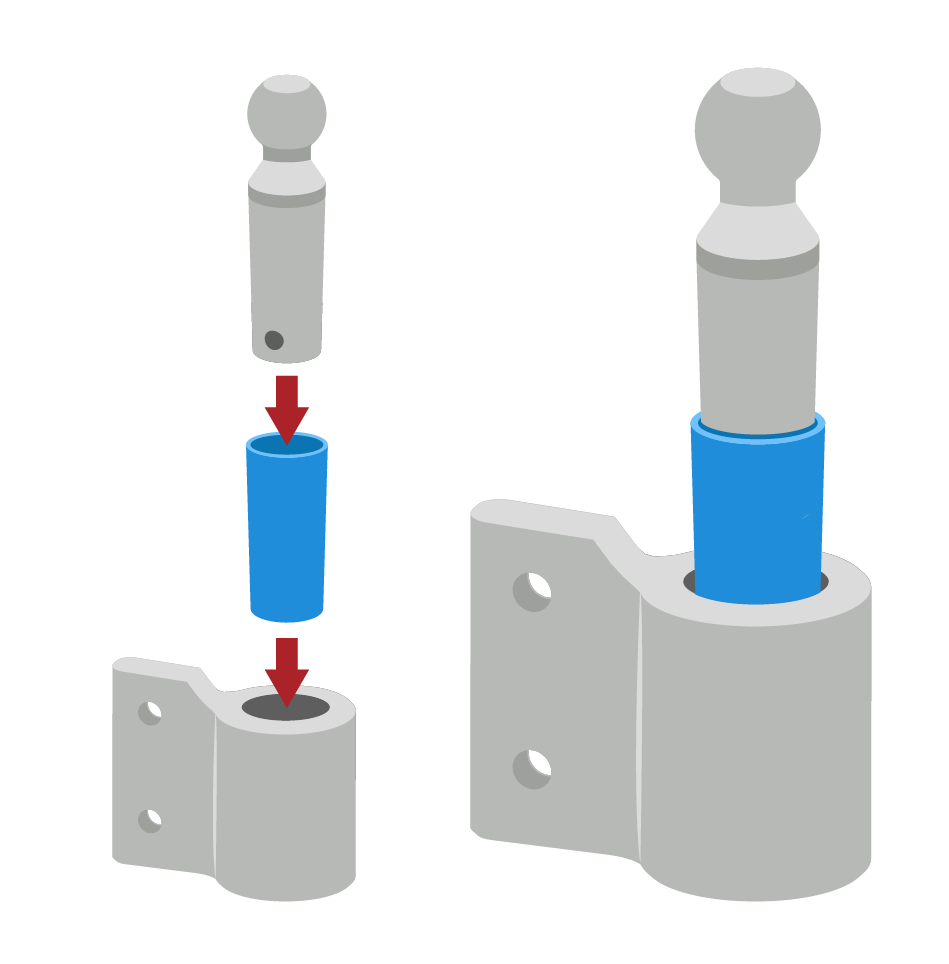

ANTI-SWAY FRICTION MATERIAL (Blue cone)

This brake-like material works between the tapered ball and ball housing to eliminate sway. The friction between the tapered ball and housing allows the hitch to “self-adjust” according to the tongue weight.

RESULT: SELF-ADJUSTING SWAY CONTROL

The heavier the tongue load, the more downward force is placed on the tapered ball which results in more weight on the brake material causing more ‘friction’ to be applied.

No Bounce - Motion-dampening Chains

We didn’t just raise the bar in weight distribution, we eliminated the need for sway bars entirely. Traditional weight distribution hitches that utilize a spring bar system, while we use a motion-dampening chain and urethane spring system.

When the spring bars are lifted, the leverage pushes the tow vehicle’s weight towards the front axle. However, after going through a dip, the spring bar can act like a diving board—loading and releasing kinetic energy, causing the truck and trailer to continue to bounce. Because our leverage is front-to-back (not up and down) the design of the Andersen Weight Distribution Hitch offers two important advantages: 1) it efficiently shifts the tow vehicle’s weight forward towards the front axle (no lifting) and 2) the chains and patented motion-dampening springs resist bounce by pulling at the right-angle to the up and down movement, eliminating unnecessary bounce. Watch the following video for a visual example of how the hitch eliminates bounce.

TRADITIONAL WEIGHT DISTRIBUTION

As the spring bars are lifted, the leverage pushes the tow vehicle’s weight towards the front axle.

ANDERSEN WEIGHT DISTRIBUTION

The Andersen Weight Distribution Hitch shifts the tow vehicle’s weight forward towards the front axle (without any lifting).

RESULT: UNNECESSARY BOUNCE

The spring bar can act like a diving board—loading and releasing kinetic energy, causing the truck and trailer to continue to bounce.

RESULT: MOTION-DAMPENING ELIMINATES BOUNCE

The chains and patented motion-dampening springs resist bounce by pulling at the right-angle to the up and down movement, eliminating unnecessary bounce.